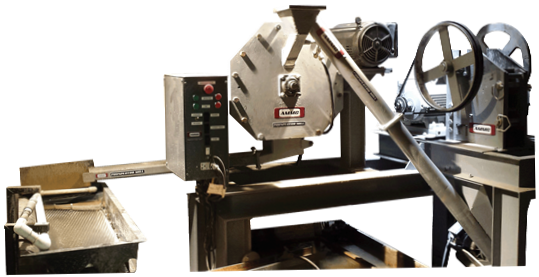

AMMC Prospector Mill

$ 45,000.00

The compact size and affordability of these patent pending mills make them perfect for any size hard rock milling application. This small-footprint mill maximizes production and efficiency. For larger hard rock mining applications the Prospector Mill allows bulk samples to be weighed and milled onsite enabling you to accurately calculate the ore grade. Modern gravity separation technology alleviates the need for toxic chemicals while retaining maximum precious metal recovery ratios.

The AMMC Prospector Mill (PATENT PENDING #1391942) hard rock mill is uniquely engineered to provide the highest measure of durability and efficiency in a very compact application. The Prospector Line was designed from the ground up around the world renowned RP4 shaker table from Global Mining Solutions. Much of the Prospetor’s durability comes from the engineering of the impact crusher and jaw crusher which are made from the highest level of abrasion resistant materials. When you purchase a Prospector Line mill, everything is included to begin milling ore; jaw crusher, impact crusher, classifying screen and an RP4 shaker table to sort it all out.

We wanted to get the maximum recovery from our precious metal ore. Other gold mills just weren't capable of making this an efficient process. After researching the economic feasibility and ecological impacts of different recovery methods we, without hesitation, chose gravity separation. Not only does this drastically reduces the processing cost per ton, but it eliminates harmful chemicals from the equation. We went with the RP4 Shaker Table because of its proven history and were not disappointed. Our jaw crusher, impact crusher assembly and classifying screen were specifically engineered to produce the optimal mesh curve for the RP4.

- It crushes and classifies ore in one pass.

- By achieving the desired mesh curve you will get the optimum liberation of gold through gravity separation.

- This American made and manufactured product ships pre-wired and plumbed and includes an RP4 shaker table. Once you hook up a half-inch water line and single phase 220 power you are ready to start milling. The only other thing you need to supply is the high-grade ore.

- The compact footprint (approx. 35 sq ft) allows the Prospector to be easily trammed to underground hard rock mines or transported to any global location without too much effort.

Click Here for Purchase Information!